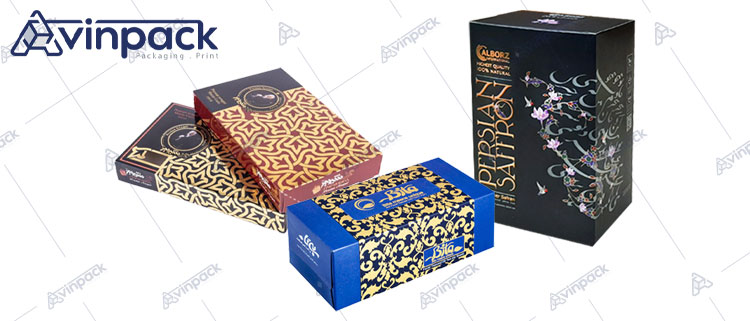

After-printing services are a set of services performed on the surface of various types of cardboard packaging. On the other hand, these services make the box more durable and attractive.

After-printing services today with the development of the printing and packaging industry, many materials are used to make printing coating appealing. They are Cellophane, Varnish, Goldsmith, UV, Embossing, and Metalized printing.

Cellophane

After-printing services nowadays are really practical. Cellophane is a thin layer of plastic that is stretched on packaging boxes which is both elegant, waterproof, and resistant. Cellophane operation is performed by two methods, thermal and mechanical which both have special devices.

Using cellophane in packaging keeps your box safe and makes it to sounds more durable. Why more beautiful? Of course to absorb people to buy your goods these processes can high- light your brand and will increase your income. In addition, cellophane can supply a great solution to your establishment packaging.

Varnish

Varnish is a clear liquid that is painted onto things to protect them or the hard shiny surface produced by this. This service is added to the packaging or box according to the wishes of the customers and makes it more stunning than luxurious packaging.

Varnish is inserted on the surface of the box by the printing machine. It has a slight gloss compared to UV and glossy cellophane, but one of its advantages is not giving back the color of the box. The packaging becomes pale during delivery and handling which can be prevented by doing varnish.

Type of varnish coating

Gloss

If we want your box to stand out, be notified to use this item. This kind of varnish cause your packaging looks beautiful and shine. Therefore, by using gloss in your box, you can attract customers, and also it will make your brand stand out.

Matte

As the name of this service applies, it is not reflective. Color is matte varnish appears duller

Goldsmith

Goldsmith is in such a way that desired designs hit the gold foils or different colors of this product on the printed- cardboard or poster through a metal. In addition, this service makes the boxes more attractive and charming.

UV

UV is the abbreviation of ultraviolet, a coating service that utilizes ultraviolet light. This ray is used to dry ink which causes the ink to dry quickly and with high accuracy. UV also makes the packaging shiny but to some extent increases the resistance of the boxes to water.

Embossing

Emboss is used to highlight cardboard evenly which is mostly used to prevent forgery and fraud. This type of service can be utilized before and after printing. The designs of this service are expensive and limited due to the initial costs.

Embossing is used to insert a logo, brand, photo or emblem, and other items on the packaging. For these purposes, two stereotypes are used in the format of material which makes the desired part more prominent.

Metalized printing

Metalized printing is a model of special printing pointing serviced such as a hybrid. In this model, metalized sheets (gold, silver, or other colors of the product) are drawn on cardboard like cellophane and then print.

The printing process of this service is slightly different from ordinary offset printing, so if you want to print on cardboard through zinc and the desired design will be printed.

Effects of the after-printing services on the quality of products

In the cardboard boxes, after-printing services have special and unique importance due to their advertising aspects and the symbol of the manufacturer. As you know, the unprinted box only acts as a protector of that product and cannot represent the good and its brand.

Read more: offset printing

Therefore, if each manufacturer or seller wants his or her goods to be known, they must be printed on the packaging. In addition, other services can be formed that call after printing services.

Advantages of after-printing services

One of the reasons for the progress of some successful companies in the field of the production and manufacture of cardboard boxes is the wide range of the after printing services and their variety which is an important step for the development of such companies. These services in addition to the advertising aspect and the introduction of the desired product, increase the number of the applicants and as a result, sells more products.

Effects of after-printing services

- It will have more durability in mind.

- This causes your products to be seen and will increase sales amount.

- Make your package seems good-looking.

Summary

In this article, we talked about after-printing services, their types, and their effects on product quality. Did you know that these services can add beauty to the box and make it strong? what a great impact they have on the high sales of the production and more profit performance in thoughts!

AVINPAC company with more than 10 years of activity in manufacturing and producing boxes and cartons in Karaj and Tehran, can help you to have convenient and affordable carton packaging. For more information contact us with mentioned numbers.

Thank you for joining us.

دیدگاه خود را ثبت کنید

تمایل دارید در گفتگو شرکت کنید؟نظری بدهید!