Offset printing and an explanation of how this type of printing works, but before we address this issue in this article, it should be said very briefly that offset printing and types of printing are very important in packaging. From the past to the present, the printing industry has been able to make countless progress, and by examining the history of the emergence of printing machines and efforts to produce modern machine in this industry, we can understand the importance of this issue.

What is offset printing?

Offset printing generally consists of 4 main colors blue(cyan), red(megenta0, yellow(Yellow) and black(Black) and in some models are needed and in special cases are used. Offset printing through a plate or the same size as it is today based on the design and color by the laser, it illuminate on a metal sheet called zinc, and the parts of the surface of the sheet that light has hit do not disappear in the emergence unit, and as a result, the role of the design by the tram (small dots) is created.

Offset printing products

Offset printing is mostly used on paper and cardboard and products such as posters, catalogs, business cards, various types of card board packaging, office sets, envelopes, books, magazines, newspapers and any kind of products made of paper, cardboard, plates. This type of printing is used to produce metal and plastic in high circulation and quality.

Know more: packaging carton price

Offset printing machine

Offset printing machine has different models, the main difference of which is the number of color columns and the print size of the machine. The meaning of the printed size is the size in which the printing machine can print or support on paper and card board.

The colored columns of the device are between 1 to 7 columns, which is normally 4 columns, and in special cases there are up to 16 columns, and each column is a sign of one color, and as you can see, these column are colored column ( printing towers) is called a machine. Offset printing is different from digital because digital printing is used for a limited number of times ad works similarly to the structure of a printed.

Steps of offset printing

To achieve an offset printing, it is necessary to follow the steps in order to achieve a suitable offset printing according to the product packaging needs. According to experience, these cases are looked at superficially and in the end, desired output is not received.

Design

The first and most important step in all types of printing systems, especially offset, is design. Design is not about editing an image or merging multiple images together. Design is done to create and effort on the product and brand so that it can communicate with its audience, which is the customer and the out put of this relationship may be better to sell the product or buy that by customer. There are many designs softwares in the printing industry, the most widely used of which are Corel, Illustrator or 3ds Max.

Know more: modern box making

Litography ( preparation of zinc)

Zinc or the same plate as describe above is the coversion of a digital image or the same designed to a tactile mechanical plate in the general definition of litography. In some cases this is also called industrial photography.

It is a Greek work and lito means stone and graphic means engraving. Litographic output was called film in ancient times, which is now called plate or zinc. After preparing zinc from design files with lighting, one zinc is prepared from each color and if it is four colors, 4 zinc is prepared.

Printing operation

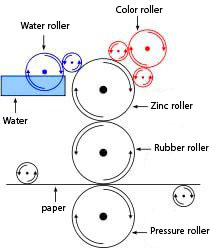

As you have noticed so far, offset printing machines have different models that, have a number of colored columns. In the picture below, you can see the internal structure of a colored column in the offset machine and get acquainted with its director.

- Paint roller are used to add and substract the amount and types of color.

- The water roller cleans the zinc roller.

- Zinc rollers or plate is described at the beginning of this article.

- Rubber roller are printed on paper by this design roller.

- Pressure rollers increase and decrease the amount of pressure and the amount of link based on the thickness of the paper. rolling cylinders are also called roller cylinders.

Avin Pack carton Industry

Avin Pack Company, with more than a decade of activity in the field of carton packaging and cardboard packaging for various products for supply to the domestic markets and export to foregin markets with modern printing and packaging machines, is ready to enter into contracts with respected manufacturers and traders.

the laminated cartons are produced based on offset printing. this printing is more useful and nice to use clear colors and show logos better.