Carton sheet making and sheet production is one of the most important and indelible steps for making cartons. The main element of the carton is the sheet, that is, without the sheet and its industry, the carton can not be produced. There are different types of sheets, the most common of which are kraft, liner and top white.

Carton sheet

Carton sheet and sheet making is done through a process. Paper itself is a product, ie it can not be produced from sheet paper, but the ingredients of both are almost the same, which is added in sheet making.

Read more: CARTON MAKING JOB

The important point is that you should contact the price of each sheet to find out the price, because the prices vary according to market fluctuatiuons.

Flute

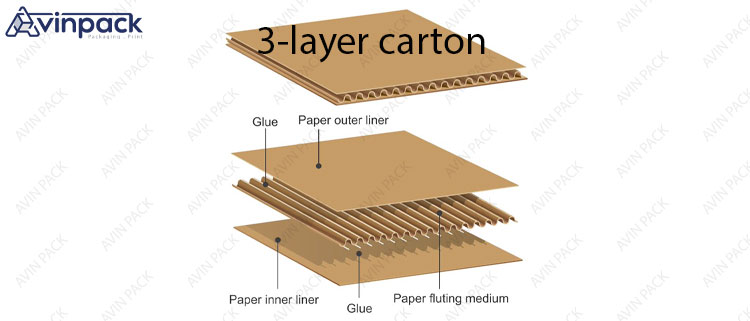

Carton flute is the same corrugated paper that is placed between the flat layers of the carton. The wavyness of the flutes depends on their type. The range of flute steps in the sheet making is divided of cartons. In this article, we will examine the application, thickness and number of congresses.

Read more: CARTON FLUTE

A flute: This flute is about 105-125 congresses per meter of sheet, which is used for fragile and objects such as household appliances and electrical ones.

B flute: is one of the most suitable types of flute in cartons for breakable accessories with high impact strength. B flute, which has an average of 125-150 teeth with a thickness of 2-3 mm, can withstand a weight of 13 kg.

C flute: The resistance of the C flute is less than of A flute and B. Cartons made with such a flute are much more practical and are used for packaging various products.

E flute: Carto9ns and boxes made of this typed of flute are used for applications such as shoe boxes, which have goodm resistance to pressure and crushing and protect boxes from such damage.

F flute: F flute is one o the least used flute trains in carton making because is resistance is very low compared to other flutes and it is used for packaging perfume, sprays and cosmetics.

All of these flutes are used to make cartons and boxes of various products, but for three-layer and five-layer cartons, a combination of such flutes is usually used together.

For example, the combination of BC flutes is used to make 5 layer cartons, because the combination of these two flutes gives good resistance to the packed carton and is used for heavy products that need protection and care during transportation.

Carton layer

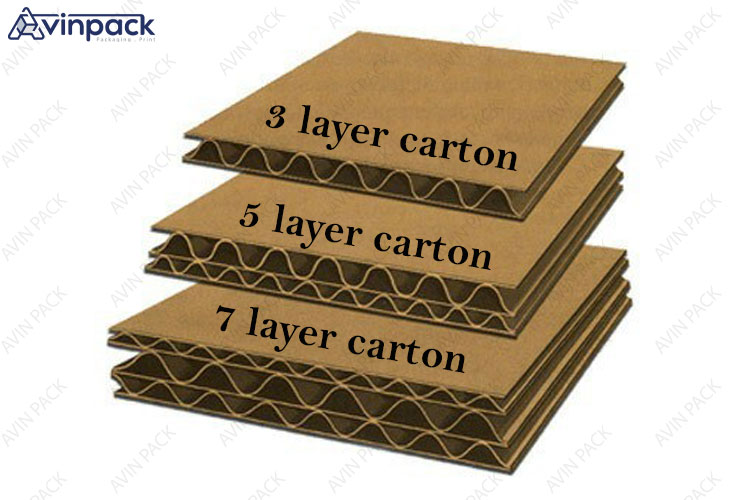

By reading the above, you find out what kind of sheet and what kind of combination of flutes are made for different types of cartons. Cartons are produced in 3-layer, 5-layer and in some rare cases 7-layer types. These cartons are made for various products depending on customer needs and their weight.

3-layer cartons produced by B,C flutes are the most widely used cartons for packaging goods because with their high strength, they can work well in protecting products and cover most products.

5-layer carton: the strength and durability of 5-layter cartons is slightly higher than that of 3-layer cartons because two layers of composite flute have been used in its productions.

These cartons are used for products that have a high percentage of breakage and damage during transportation.

In this article, we have provided you with information about cardboard flutes ad their layers of sheet making and how to produce sheets. By reading this article, you have gained enough knowledge about how to provide sheets and cartons, you can well find out what kind of sheets or flutes are suitable for your cartons.

About Us

Avin pack sheet manufacturing company, with more than two decades, of experience, with an active and diligent team in the production of cartons and packaging beads, with up-tp-date and modern machines, in addition to packaging various types of packaging, also produced sheet products in the factory.

Dear ones, you can receive advice in the sales until from the section (contact us) in choosing the typed of sheets and types of cartons and apply for order registration.

yes. some sizes are normal and standard and we can use them for any product.